- About TPE

About TPE

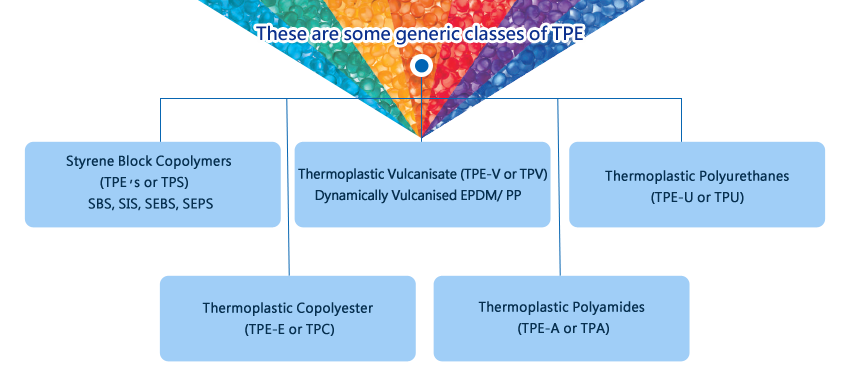

Briefly, TPE are a series of rubber-like materials that combine the features of rubber with the recyclability and processing advantages of plastics.

The science bit; like thermoplastics, when heated and with the application of shear force, TPE become free-flowing. When cooled, it then regains its original structure and stability.

TPE is purely physical cross-linking, different from thermoset rubbers which are chemically cross-linking. This means that TPE could be reversed through the application of heat. This makes it possible to re-use all production scrap and end-of-life products can be easily reprocessed.

TPE has elasticity similar to thermoset rubbers. The softness and hardness value is measured on the Shore Durometer Scale. Super Asia Polyblend can provide ultra-soft materials measuring 0 Shore A through to rigid materials measuring up to 65 Shore D, and every variation in-between.

- TPE replaces more and more materials these days, owing to its high-performance, excellent flexibility, ease of process and stability.

- Advantage of TPE:

- Odorless and non- toxic.

- Softness and good hand feeling.

- Great anti-slip (even with water)

- Easy to process and color.

- Excellent elongation.

- Perfect resilience.

- Low compression set.

- Good rebound elasticity.

- Resistant to acid and alcohol based solvents.

- Excellent weather ability (UV and ozone)

- Abundance of applications:

- Medical supplies

- Daily products

- Baby products

- Building and construction.

- Hand tools

- Foot wear and sporting goods

- Packaging and food container seal.

- Wire, cables and trim.

- Electronics& electrical devices.

- Automotive and parts.

New uses for TPEs are being developed all the time. If you have other application requirements, we are eager to help develop it with you.